Training on the Latest Measurement Techniques in Instrumentation

In the present era, instrumentation is recognized as a fundamental pillar of various industries and research sciences. This field, utilizing advanced technologies, can measure and analyze accurate and reliable data from multiple parameters. Given the continuous advancements in this domain, familiarity with new measurement techniques has become particularly important. This article will explore the latest measurement techniques in instrumentation and explain how to utilize them effectively.

Smart Sensors and New Technologies

Smart sensors represent one of the most significant advancements in measurement techniques. These sensors, capable of local data processing and online transmission, enable real-time monitoring and control. New technologies in sensors include:

- High-Precision Sensors: These sensors can measure parameters with very high accuracy, suitable for sensitive applications like medical and research fields.

- Multifunctional Sensors: Sensors capable of measuring multiple parameters simultaneously, facilitating the optimization of industrial processes.

- Upgradeable Sensors: These sensors can be easily upgraded and updated, allowing them to keep pace with technological advancements.

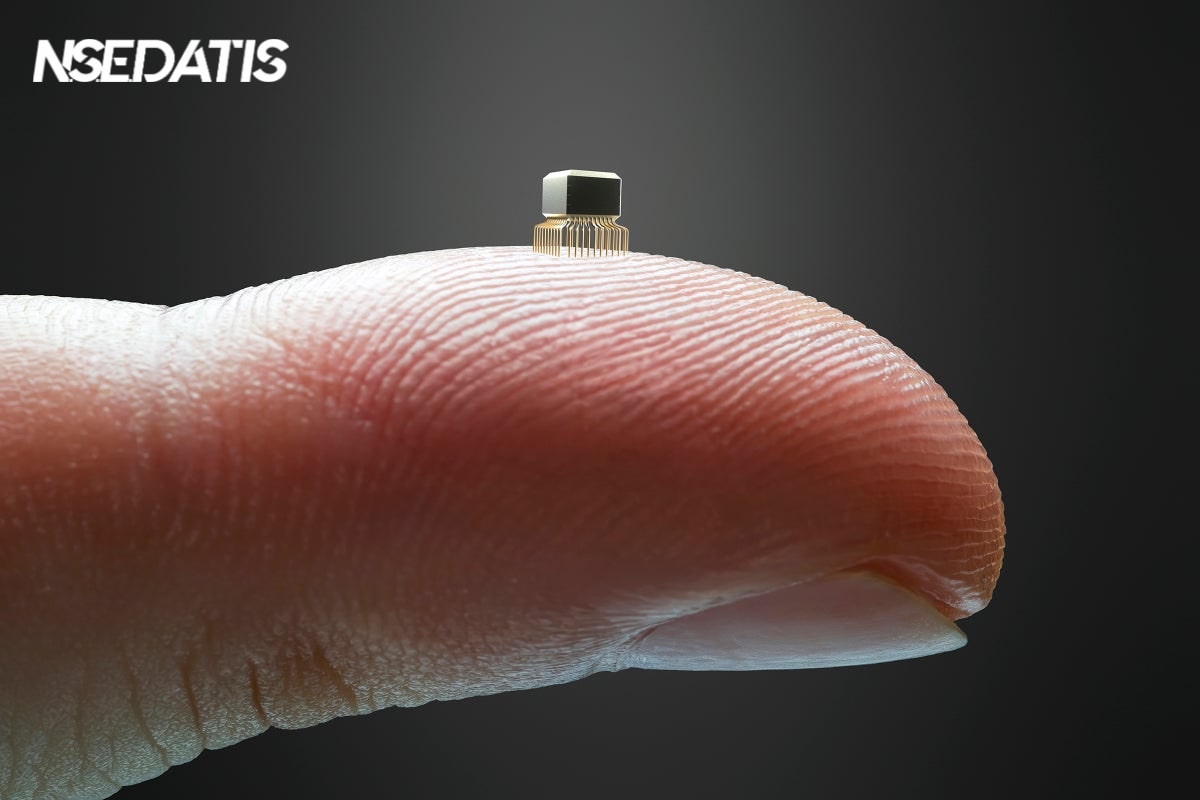

Nanotechnology and Nanoscale Sensors

Nanotechnology is becoming a powerful tool in the instrumentation industry. Nanoscale sensors, due to their small size and high sensitivity, can measure the smallest changes at the nanoscale. This technology offers:

- High Accuracy: Nanoscale sensors can detect very small changes in parameters that are undetectable by conventional sensors.

- Small Size: Their tiny size allows them to be installed in small and hard-to-reach locations.

- Fast Response: These sensors respond quickly to environmental changes, improving real-time measurement capabilities.

Advanced Laser Measurement Techniques

Laser measurement techniques, known for their high accuracy and non-contact measurement capabilities, are used in various industries. These techniques include:

- Distance Measurement Lasers: Lasers used for precise distance measurement between two points, applicable in mapping and civil engineering.

- Speed Measurement Lasers: Lasers capable of measuring the speed of moving objects with high accuracy are used in the automotive and aerospace industries.

- Imaging Lasers: Lasers are used to create three-dimensional images of surfaces and analyze them.

Radio Wave and Microwave Measurement Techniques

Radio waves and microwaves are also advanced measurement techniques. These include:

- Microwave Radar: Used for measuring the distance and speed of objects in various environments, applicable in meteorology and military fields.

- Radio Wave Motion Detection Sensors: Sensors that detect motion and changes in complex environments, are used in security and surveillance systems.

- Microwave Material Detection: This technique is used for identifying and analyzing material compositions in industrial and research processes.

Also, read “Comparison of ultrasonic and radar surface measurement”

Biometrics-Based Measurement Techniques

Biometric technologies, especially in medical and security fields, are advancing rapidly. These techniques include:

- Fingerprint and Iris Recognition: Techniques used for identifying and verifying individuals, employed in security and access control systems.

- Biological Parameter Measurement: Biometric tools capable of continuously measuring biological parameters such as heart rate, blood pressure, and body temperature, contributing to improved healthcare.

- Behavioral Analysis: Techniques capable of analyzing behavior and movement patterns, used in psychological and security research.

Intelligent Control and Measurement Systems

Intelligent control and measurement systems play a crucial role in large and complex industries. These systems include:

- Programmable Logic Controllers (PLC): Controllers used for process automation and precise system control, applicable in manufacturing and process industries.

- Web-Based Monitoring and Control Systems: Systems that allow users to monitor and control their systems online from any location.

- Advanced Data Analysis Systems: Systems capable of analyzing big data and simulating processes accurately, aiding in strategic decision-making.

Also, read “Discovering the wonderful world of pressure measurement methods”

Challenges and Future of Measurement Techniques

Despite significant advancements in measurement techniques, some challenges need to be addressed:

- Accuracy and Reliability: Each measurement technique must continually improve to maintain accuracy and reliability.

- Cost and Complexity: Advanced techniques may be costly and complex, necessitating a detailed assessment of costs and benefits.

- Development and Updates: With rapid technological changes, there is a need for continuous updates and new training to utilize the latest techniques effectively.

Conclusion

Measurement techniques in instrumentation are continually evolving and advancing. Familiarity with the latest techniques and technologies enables professionals and enthusiasts to effectively leverage these advancements, improving the performance and accuracy of their systems. By keeping up with new trends and ongoing education, more optimal results can be achieved and resources can be utilized more effectively.